Specialist in automated packaging according to your needs.

Compopack has extensive experience in industrial automation and packaging systems. With our innovative, environmentally sustainable approach, we can help you design and prototype new packaging, processes and, if necessary, complete automated solutions.

Pharmaceuticals

Scope of work:

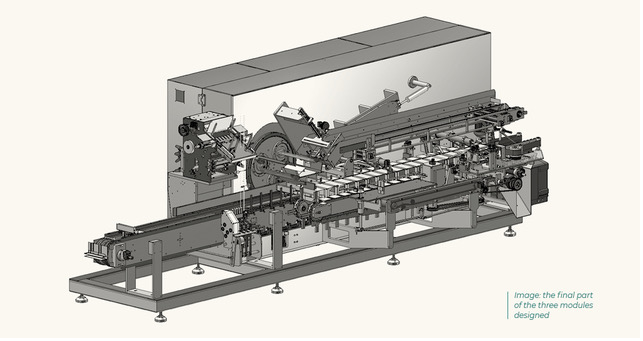

The Tofflon machine was a three-module machine that:

→ It forms glass vials at a speed of 1000 ppm and fills them with liquid in a completely aseptic environment, sorts the vials and packs them in the forming cell;

→ Packs bottles into carton (including insertion of package insert) – 300 ppm

→ Packs batch cartons in foil ready for arrangement into boxes or shelves

What compopack did:

→ Machine prototype in compliance with EU and US pharmaceutical requirements;

→ Process design including complete redesign of the supply chain process meeting 6S Black-Belt standards;

→ As a result, the machine was internationally recognized and certified. The design is a model for all new generation machines (18 units in this series were delivered to customers in China)

Food industry

Scope of work:

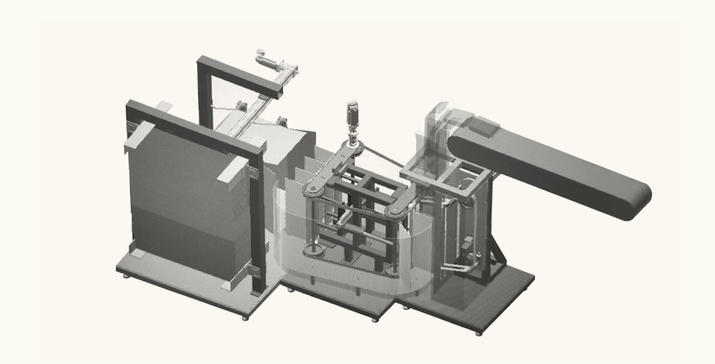

→ The specification received was a traditional RSC packaging machine, which reduces the amount of energy for a semi-automatic solution for packaging potato chips.

→ The available space required a complete redesign of the packaging process when moving from a semi-automatic to a fully automatic solution;

What compopack did:

→ We reduced the “air gap” and managed to complete filled bags without using traditional motorized robotic pick & place systems, which were too large and consumed too much energy.

→ During the conceptual phase, we used the Standard Stage-Gate-system methodology, which was redesigned for the process and measured energy savings compared to traditional solutions;

Drinks

Scope of work:

→ We have designed a new packaging solution for the production of coffee capsules that maintains shape, function and is cost-effective at the same time.

→ The new solution had to be perfectly interchangeable with existing beverage dispensers.

→ A minimum shelf life system was designed and later successfully tested in the COMPOPACK laboratory.

What compopack did:

→ A compatibility survey of advanced materials (plastic, aluminum, and others) was conducted to ensure that the machine is usable in both old and new technological systems.

→ We produced a prototype to verify the mechanical performance and the closing process.

→ After obtaining the patent, we installed ECOPOD in well-known coffee capsule manufacturers.